UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

FORM 10-K

|

| |

x | ANNUAL REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 |

For the fiscal year ended December 31, 2014

OR

|

| |

¨ | TRANSITION REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 |

For the transition period from ____________ to ____________.

Commission File Number: 0-19582

OLD DOMINION FREIGHT LINE, INC.

(Exact name of registrant as specified in its charter)

|

| | |

VIRGINIA | | 56-0751714 |

(State or other jurisdiction of incorporation or organization) | | (I.R.S. Employer Identification No.) |

500 Old Dominion Way

Thomasville, NC 27360

(Address of principal executive offices)

(Zip Code)

(336) 889-5000

(Registrant’s telephone number, including area code)

Securities registered pursuant to Section 12(b) of the Act:

|

| | |

Title of each class | | Name of each exchange on which registered |

Common Stock ($0.10 par value) | | The NASDAQ Stock Market LLC (NASDAQ Global Select Market) |

Securities registered pursuant to Section 12(g) of the Act: None

Indicate by check mark if the registrant is a well-known seasoned issuer, as defined in Rule 405 of the Securities Act. Yes ý No ¨

Indicate by check mark if the registrant is not required to file reports pursuant to Section 13 or Section 15(d) of the Act. Yes ¨ No ý

Indicate by check mark whether the registrant (1) has filed all reports required to be filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the preceding 12 months (or for such shorter period that the registrant was required to file such reports), and (2) has been subject to such filing requirements for the past 90 days. Yes ý No ¨

Indicate by check mark whether the registrant has submitted electronically and posted on its corporate Website, if any, every Interactive Data File required to be submitted and posted pursuant to Rule 405 of Regulation S-T (§232.405 of this chapter) during the preceding 12 months (or for such shorter period that the registrant was required to submit and post such files). Yes ý No ¨

Indicate by check mark if disclosure of delinquent filers pursuant to Item 405 of Regulation S-K (§229.405 of this chapter) is not contained herein, and will not be contained, to the best of registrant’s knowledge, in definitive proxy or information statements incorporated by reference in Part III of this Form 10-K or any amendment to this Form 10-K. ý

Indicate by check mark whether the registrant is a large accelerated filer, an accelerated filer, a non-accelerated filer, or a smaller reporting company. See the definitions of “large accelerated filer,” “accelerated filer” and “smaller reporting company” in Rule 12b-2 of the Exchange Act.

|

| | | | | |

Large accelerated filer | x | | | Accelerated filer | ¨ |

Non-accelerated filer | ¨ | | | Smaller reporting company | ¨ |

(Do not check if a smaller reporting company) | | | |

Indicate by check mark whether the registrant is a shell company (as defined in Rule 12b-2 of the Act). Yes ¨ No ý

The aggregate market value of voting stock held by non-affiliates of the registrant as of June 30, 2014 was $4,085,227,825, based on the closing sales price as reported on the NASDAQ Global Select Market.

As of February 25, 2015, the registrant had 85,925,587 outstanding shares of Common Stock ($0.10 par value).

DOCUMENTS INCORPORATED BY REFERENCE

Certain portions of the Company’s Proxy Statement for the 2015 Annual Meeting of Shareholders are incorporated by reference into Part III of this report.

INDEX

|

| | |

| |

| | |

Item 1 | | |

Item 1A | | |

Item 1B | | |

Item 2 | | |

Item 3 | | |

Item 4 | | |

|

| | |

| |

| | |

Item 5 | | |

Item 6 | | |

Item 7 | | |

Item 7A | | |

Item 8 | | |

Item 9 | | |

Item 9A | | |

Item 9B | | |

|

| | |

| |

| | |

Item 10 | | |

Item 11 | | |

Item 12 | | |

Item 13 | | |

Item 14 | | |

FORWARD-LOOKING INFORMATION

Forward-looking statements appear in this Annual Report, including but not limited to Item 7, “Management’s Discussion and Analysis of Financial Condition and Results of Operations,” and in other written and oral statements made by or on behalf of us. These forward-looking statements include, but are not limited to, statements relating to our goals, strategies, expectations, competitive environment, regulation, availability of resources, future events and future financial performance. Such forward-looking statements are made pursuant to the safe harbor provisions of the Private Securities Litigation Reform Act of 1995. These forward-looking statements typically can be identified by such words as “anticipate,” “estimate,” “forecast,” “project,” “intend,” “expect,” “believe,” “should,” “could,” “may,” or other similar words or expressions. We caution readers that such forward-looking statements involve risks and uncertainties that could cause actual events or results to differ materially from those expressed or implied herein, including, but not limited to, the risk factors detailed in this Annual Report.

Our forward-looking statements are based on our beliefs and assumptions using information available at the time the statements are made. We caution the reader not to place undue reliance on our forward-looking statements as (i) these statements are neither a prediction nor a guarantee of future events or circumstances and (ii) the assumptions, beliefs, expectations and projections about future events may differ materially from actual results. We undertake no obligation to publicly update any forward-looking statement to reflect developments occurring after the statement is made.

PART I

ITEM 1. BUSINESS

Unless the context requires otherwise, references in this report to “Old Dominion,” the “Company,” “we,” “us” and “our” refer to Old Dominion Freight Line, Inc.

Overview

We are a leading, less-than-truckload (“LTL”), union-free motor carrier providing regional, inter-regional and national LTL services, which include ground and air expedited transportation and consumer household pickup and delivery through a single integrated organization. We were the fifth largest LTL motor carrier in the United States, as measured by 2013 revenue, according to Transport Topics. In addition to our core LTL services, we offer a broad range of value-added services including international freight forwarding, container drayage, truckload brokerage, supply chain consulting and warehousing. Our services are complemented by our technological capabilities, which we believe provide the tools to improve the efficiency of our operations while empowering our customers to manage their individual shipping needs. More than 95% of our revenue is derived from transporting LTL shipments for our customers, whose demand for our services is generally tied to industrial production and the overall health of the U.S. domestic economy.

We have increased our revenue and customer base over the past five years primarily through organic growth. Our infrastructure allows us to provide next-day and second-day service within each of our six regions covering the continental United States, as well as inter-regional and national service between these regions. To support our ongoing expansion, we added 12 new service centers during the past five years for a total of 222 at December 31, 2014.

We believe our growth can be attributed to our focus on meeting our customers’ complete supply chain needs from a single point of contact while providing a superior level of customer service at a fair and equitable price. Our integrated structure allows us to offer our customers consistent high-quality service from origin to destination, and we believe our operating structure and proprietary information systems also enable us to efficiently manage our operating costs.

We were founded in 1934 and incorporated in Virginia in 1950. Our principal executive offices are located at 500 Old Dominion Way, Thomasville, North Carolina 27360. Please refer to the Balance Sheets and Statements of Operations included in Item 8, “Financial Statements and Supplementary Data” in this report for information regarding our total assets, revenue from operations and net income.

Our Industry

Trucking companies provide transportation services to virtually every industry operating in the United States and generally offer higher levels of reliability and faster transit times than other surface transportation options. The trucking industry is comprised principally of two types of motor carriers: LTL and truckload. LTL carriers typically pick up multiple shipments from multiple customers on a single truck and then route that freight for delivery through service centers where the freight may be transferred to other trucks with similar destinations. In contrast, truckload carriers generally dedicate an entire truck to one customer from origin to destination.

According to the American Trucking Associations, total U.S. freight transportation revenue in 2013 was $840.0 billion, of which the trucking industry accounted for 81.2%. The LTL sector had revenue in 2013 of $54.4 billion, which represented 6.5% of total U.S. freight transportation revenue. In contrast to truckload carriers, LTL motor carriers require expansive networks of local pickup and delivery (“P&D”) service centers, as well as larger breakbulk, or hub, facilities. Significant capital is required to create and maintain a network of service centers and a fleet of tractors and trailers. The high fixed costs and capital spending requirements for LTL motor carriers make it difficult for new start-up or small operators to effectively compete with established carriers. In addition, successful LTL motor carriers generally employ, and regularly update, a high level of technology-based systems and processes that provide information to customers and help reduce operating costs.

The LTL industry is highly competitive on the basis of service and price and has consolidated significantly since the industry was deregulated in 1980. Based on 2013 revenue as reported in Transport Topics, the largest 10 and 25 LTL motor carriers accounted for approximately 47.3% and 57.8%, respectively, of the total LTL market. We believe consolidation in our industry will continue due to customer demand for transportation providers offering both national and regional LTL as well as other complementary value-added services.

Competition

We compete with regional, inter-regional and national LTL carriers and, to a lesser extent, with truckload carriers, small package carriers, airfreight carriers and railroads. We also compete with, and provide transportation services to, third-party logistics providers that determine both the mode of transportation and the carrier. We compete with several large and diversified transportation service providers, each of which may have a broader global network and a wider range of services than we do. Competition is based primarily on service, price and business relationships. We believe we are able to compete effectively in our markets by providing high-quality and timely service at a fair and equitable price.

Throughout our organization, we continuously seek to improve customer service by maximizing on-time performance and minimizing cargo claims. We believe our transit times are generally faster than those of our principal national competitors, in part because of our more efficient service center network, use of team drivers and proprietary technology. In addition, we provide greater geographic coverage than most of our regional competitors. Our diversified mix and scope of regional, inter-regional and national LTL service, combined with our value-added service offerings, enables us to provide our customers with a single source to meet their shipping and logistics needs. We believe this provides us with a distinct advantage over most of our regional, multi-regional and national competition.

We utilize flexible scheduling and train our employees to perform multiple tasks, which we believe allows us to achieve greater productivity and higher levels of customer service than our competitors. We believe our focus on employee communication, continued education, development and motivation strengthens the relationships and trust among our employees.

Service Center Operations

At December 31, 2014, we operated through 222 service center locations, of which we owned 176 and leased 46. We operate a total of ten major breakbulk facilities located in Rialto, California; Atlanta, Georgia; Chicago, Illinois; Indianapolis, Indiana; Greensboro, North Carolina; Harrisburg, Pennsylvania; Memphis and Morristown, Tennessee; Dallas, Texas; and Salt Lake City, Utah, while using various other service centers for additional limited breakbulk activity in order to serve our next-day markets. Our service centers are strategically located in six regions of the country so that we can provide the highest quality service and minimize freight rehandling costs.

Our service centers are responsible for the pickup and delivery of freight within their local service area. Each night, our service centers load outbound freight for transport to other service centers for delivery. All inbound freight received by the service center in the evening or during the night is generally scheduled for local delivery the next business day, unless a

customer requests a different delivery schedule. Our management reviews the productivity and service performance of each service center on a daily basis to help ensure quality service and efficient operations.

While we have established primary responsibility for customer service at the local service center level, our customers may access information and initiate transactions through our centralized customer service department located at our corporate office or through several other gateways, such as our website, mobile applications, electronic data interchange (“EDI”), email and fax notification systems and automated voice response systems. Our systems offer direct access to information such as freight tracking, shipping documents, rate quotes, rate databases and account activity. These centralized systems and our customer service department provide our customers with a single point of contact to access information across all areas of our operations and for each of our service offerings.

Linehaul Transportation

Linehaul dispatchers control the movement of freight between service centers through integrated freight movement systems. We also utilize load-planning software to optimize efficiencies in our linehaul operations. Our management team monitors freight movements, transit times, load factors and many other productivity measurements to help ensure that we maintain our high levels of service and efficiency.

We utilize scheduled routes, and additional linehaul dispatches as necessary, to meet our published transit times. In addition, we lower our cost structure by primarily using twin 28-foot trailers in our linehaul operations. The use of twin 28-foot trailers permits us to transport freight directly from its point of origin to destination with minimal unloading and reloading, which also reduces cargo loss and damage expenses. We utilize long-combination vehicles, such as triple 28-foot trailers and combinations of 48-foot and 28-foot trailers, in states where permitted. Twin trailers and long-combination vehicles permit more freight to be transported behind a tractor than could otherwise be transported by one trailer.

Tractors, Trailers and Maintenance

At December 31, 2014, we owned 6,907 tractors. We generally use new tractors in linehaul operations for approximately three to five years and then transfer those tractors to P&D operations for the remainder of their useful lives. In many of our service centers, tractors perform P&D functions during the day and linehaul functions at night to maximize tractor utilization.

At December 31, 2014, we owned 27,259 trailers. We primarily purchase new trailers for our operations; however, we occasionally purchase pre-owned equipment that meets our specifications. The purchase of pre-owned equipment can provide an excellent value but also can increase our fleet’s average age. The table below reflects, as of December 31, 2014, the average age of our tractors and trailers:

|

| | | | | | |

Type of Equipment | | Number of Units | | Average Age (In years) |

Tractors | | 6,907 |

| | 4.9 |

|

Linehaul trailers | | 19,556 |

| | 5.8 |

|

P&D trailers | | 7,703 |

| | 11.8 |

|

We develop certain specifications for tractors and trailers and then negotiate the production and purchase of this equipment with several manufacturers. These purchases are planned well in advance of anticipated delivery dates in order to accommodate manufacturers’ production schedules. We believe there is sufficient capacity among suppliers to ensure an uninterrupted supply of equipment to support our operations.

The table below sets forth our capital expenditures for tractors and trailers for the years ended December 31, 2014, 2013 and 2012. For more information concerning our capital expenditures, see Item 7, “Management’s Discussion and Analysis of Financial Condition and Results of Operations – Liquidity and Capital Resources” in this report.

|

| | | | | | | | | | | | |

| | Year Ended December 31, |

(In thousands) | | 2014 | | 2013 | | 2012 |

Tractors | | $ | 91,750 |

| | $ | 59,317 |

| | $ | 113,257 |

|

Trailers | | 80,853 |

| | 70,042 |

| | 83,405 |

|

Total | | $ | 172,603 |

| | $ | 129,359 |

| | $ | 196,662 |

|

At December 31, 2014, we operated 38 maintenance centers at certain service center locations throughout our network. These maintenance centers are equipped to perform routine and preventive maintenance and repairs on our equipment.

We adhere to established maintenance policies and procedures to help ensure our fleet is properly maintained. Tractors are routed to appropriate maintenance facilities at designated mileage intervals or every 90 days, whichever occurs first. Trailers are scheduled for maintenance every 90 days.

Customers

Revenue is generated primarily from customers throughout the United States and North America. In 2014, our largest customer accounted for approximately 2.6% of our revenue and our largest 5, 10 and 20 customers accounted for approximately 9.7%, 14.8% and 21.5% of our revenue, respectively. For each of the previous three years, more than 95% of our revenue was derived from transporting LTL shipments for our customers and less than 5% of our revenue was generated from international services. We believe the diversity of our customer base helps protect our business from adverse developments in a single geographic region and from the reduction or loss of business from a single customer.

We utilize an integrated freight-costing system to determine the price level at which a particular shipment of freight will be profitable. We can modify elements of this freight-costing model to simulate the actual conditions under which the freight will be moved. Many of our customers engage our services through the terms and provisions of our tariffs and through negotiated service contracts. We also compete for business by participating in bid solicitations. Customers generally solicit bids for relatively large numbers of shipments for a period of one to two years and typically choose to enter into contractual arrangements with a limited number of motor carriers based upon price and service.

Seasonality

Our operations are subject to seasonal trends common in the trucking industry. Our operating margins in the first quarter are normally lower due to reduced demand during the winter months. Harsh weather can also adversely affect our performance by reducing demand and reducing our ability to transport freight, which could result in decreased revenue and increased operating expenses.

Technology

We continually seek to upgrade and enhance our technological capabilities, and we provide access to our systems through multiple gateways that offer our customers and employees maximum flexibility and immediate access to information. We employ vehicle safety systems, on-board and hand-held computer systems, freight handling systems and logistics technology to reduce costs and transit times. Our data systems are integrated in every level within our organization, which we believe is critical to our success and performance. Our systems are protected through physical and software safeguards, as well as redundant systems, network security measures and backup systems considered appropriate by management. We continue to focus on the development and enhancement of the technology used in our operations in order to improve the efficiency and effectiveness of our services.

Insurance

We carry a significant amount of insurance with third-party insurance carriers, but we are exposed to the risk of loss on claims up to the limit for which we hold either a self-insured retention ("SIR") or deductible. At December 31, 2014, the amounts of our SIR and/or deductibles were as follows: $2.75 million per occurrence for bodily injury and property damage (“BIPD”) claims, $100,000 per claim for cargo loss and damage, $1.0 million per occurrence for workers’ compensation claims and $400,000 per occurrence (with a $400,000 aggregate over our retention level) for group health claims.

We believe that our policy of maintaining an SIR or deductible for a portion of our risks, supported by our safety and loss prevention programs, is an effective means of managing insurance costs. We periodically review our risk exposure and insurance coverage applicable to those risks and we believe that we maintain sufficient insurance coverage.

Diesel Fuel Availability and Cost

We depend heavily upon the availability of diesel fuel to provide our transportation services. We maintain fuel storage and pumping facilities at certain service center locations as the primary source for fueling our fleet, and we utilize over-the-road fueling options at retail locations as necessary. We could be susceptible to regional and/or national fuel shortages, which could cause us to incur additional expense in order to obtain an adequate supply within our own fueling network or cause us to rely more heavily on higher-priced retail fuel.

We believe our operations and financial condition are susceptible to the same diesel fuel price increases or shortages as those of our competitors. We implemented a fuel surcharge program in August 1999, which has remained in effect since that time and is one of many components that we use to determine the overall price for our transportation services. Our fuel surcharges are generally indexed to fuel prices published by the U.S. Department of Energy (the “DOE”) that reset each week.

Employees

As of December 31, 2014, we employed 16,443 individuals on a full-time basis, none of which were represented under a collective bargaining agreement. Our full-time employees work in the following roles:

|

| | | |

Full-Time Employees | | Number of Employees |

Drivers | | 8,733 |

|

Platform | | 2,859 |

|

Fleet technicians | | 510 |

|

Sales, administrative and other | | 4,341 |

|

Total | | 16,443 |

|

As of December 31, 2014, we employed 4,484 linehaul drivers and 4,249 P&D drivers on a full-time basis. We select our drivers primarily based upon safe driving records and experience. Among other requirements, our drivers must pass a drug test, have a current U.S. Department of Transportation (“DOT”) physical and have a valid commercial driver’s license prior to employment. Once employed, drivers are required to obtain and maintain hazardous materials endorsements to their commercial driver’s licenses. Drivers, like all of our employees, are required to take pre-employment drug and alcohol tests and are randomly selected for periodic additional testing.

Since 1988, we have provided the opportunity for qualified employees to become drivers through the “Old Dominion Driver Training Program.” There are currently 2,290 active drivers who have successfully completed this training, which was approximately 26% of our driver workforce as of December 31, 2014. We believe our driver training and qualification programs have been important factors in improving our safety record and retaining qualified drivers. We reward our drivers who maintain safe driving records with bonuses of up to $3,000 per driver payable each year. Our driver safety bonuses totaled $3.1 million, $2.8 million and $2.6 million in 2014, 2013 and 2012, respectively. In addition, we have experienced an annual turnover rate for our driver graduates of approximately 5.8%, which is below our Company-wide turnover rate for all drivers of approximately 10.9%.

Governmental Regulation

We are subject to regulation by many federal governmental agencies, including the Federal Motor Carrier Safety Administration (the “FMCSA”), the Pipeline and Hazardous Materials Safety Administration and the Surface Transportation Board, which are agencies within the DOT. We are also subject to rules and regulations of various state agencies. These regulatory authorities have broad powers, generally governing matters such as authority to engage in motor carrier operations, motor carrier registration, driver hours of service, safety and fitness of transportation equipment and drivers, certain mergers, consolidations and acquisitions and periodic financial reporting. In addition, we are subject to compliance with cargo-security and transportation regulations issued by the Transportation Security Administration ("TSA") within the U.S. Department of Homeland Security.

In October 2009, the U.S. Court of Appeals for the District of Columbia Circuit ordered the FMCSA to review and re-issue rules governing hours of service for commercial truck drivers by July 26, 2011. This deadline was extended and on December 22, 2011, the FMCSA issued its final rule, which mandated compliance by July 1, 2013. The 2011 rule reduced the maximum number of hours a truck driver could work each week to 70 hours from the former 82-hour limit. The 2011 rule maintained the maximum 11-hour daily driving limit, but required drivers to take a 30-minute break prior to working beyond

eight hours. The 2011 rule also modified the “34-hour restart” provision to include two periods of rest between 1 a.m. and 5 a.m., and limited a restart to once every 168 hours. On December 16, 2014, however, the 2015 Omnibus Appropriations Bill temporarily suspended enforcement of certain aspects of the restart provisions until September 30, 2015. Specifically, the new law temporarily eliminated the requirements for two rest periods between 1 a.m. and 5 a.m. and the 168-hour minimum restart provision. During this suspension period, the law directs the Secretary of the DOT to conduct a study of the operational, safety, health and fatigue aspects of the restart provisions in effect before and after July 1, 2013.

Implementation of the 2011 rule on July 1, 2013 required us to make certain changes in our operating procedures. These changes increased our operating costs by limiting the productivity of our drivers. While the suspension of certain aspects of the restart provisions should allow us to regain some of this lost productivity, the suspension is temporary and we do not plan to make significant changes to our operations. As a result, we could continue to incur higher operating costs than we had before the 2011 rule went into effect.

We are subject to future rulemaking by the FMCSA and other regulatory agencies, which could be more stringent, require additional changes to our operations, increase our operating costs or otherwise adversely impact our results of operations.

The trucking industry is subject to regulatory and legislative changes from a variety of other governmental authorities, which address matters such as: (i) increasingly stringent environmental and occupational safety and health regulations; (ii) limits on vehicle weight and size; (iii) ergonomics; and (iv) port security. These changes may affect our business or the economics of our industry by requiring changes in operating practices, or by influencing the demand for and increasing the costs of providing our services.

Environmental Regulation

We are subject to various federal, state and local environmental laws and regulations that focus on, among other things: the emission and discharge of hazardous materials into the environment or their presence at our properties or in our vehicles; fuel storage tanks; transportation of certain materials; and the discharge or retention of storm water. Under specific environmental laws, we could also be held responsible for any costs relating to contamination at our past or present facilities and at third-party waste disposal sites, as well as costs associated with clean-up of accidents involving our vehicles. We do not believe that the cost of future compliance with current environmental laws or regulations will have a material adverse effect on our operations, financial condition, competitive position or capital expenditures for the remainder of 2015 or fiscal year 2016. However, future changes to laws or regulations may adversely affect our operations and could result in unforeseen costs to our business.

Available Information

Through our website, http://www.odfl.com, we make available, free of charge, our Annual Report on Form 10-K, Quarterly Reports on Form 10-Q, Current Reports on Form 8-K and any amendments to those reports filed or furnished pursuant to Section 13(a) or 15(d) of the Securities Exchange Act of 1934, as soon as practicable after we electronically file the material with or furnish it to the U.S. Securities and Exchange Commission (the “SEC”). The public may read or copy any document we file with the SEC at the SEC’s website, http://www.sec.gov (File No. 0-19582), or at the SEC’s Public Reference Room at 100 F Street, NE, Washington, D.C. 20549-2736. The SEC can be reached at 1-800-SEC-0330 for further information on the operation of the Public Reference Room. Information contained on our website is neither part of nor incorporated by reference into this Form 10-K or any other report we file with or furnish to the SEC.

ITEM 1A. RISK FACTORS

Various factors exist that could cause our actual results to differ materially from those projected in any forward-looking statement. In addition to the factors discussed elsewhere in this report, we believe the following are some of the important risks and uncertainties that could materially affect our business, financial condition or results of operations:

We operate in a highly competitive industry, and our business will suffer if we are unable to adequately address potential downward pricing pressures and other factors that may adversely affect our operations and profitability.

Numerous competitive factors could impair our ability to maintain our current profitability. These factors include, but are not limited to, the following:

| |

• | we compete with other transportation service providers of varying sizes, some of which may have more equipment, a broader global network, a wider range of services, greater capital resources or other competitive advantages; |

| |

• | some of our competitors may reduce their prices to gain business, especially during times of reduced growth rates in the economy, which may limit our ability to maintain or increase prices or maintain revenue; |

| |

• | we may be unable to continue to collect fuel surcharges or our fuel surcharge program may become ineffective in mitigating the impact of fluctuating costs for fuel and other petroleum-based products; |

| |

• | many customers reduce the number of carriers they use by selecting “core carriers” as approved transportation service providers and we may not be selected; |

| |

• | many customers periodically accept bids from multiple carriers for their shipping needs, and this process may depress prices or result in the loss of some business to competitors; |

| |

• | some customers may choose to operate their own private trucking fleet or may choose to increase the volume of freight they transport if they have an existing private trucking fleet; |

| |

• | some customers may choose to consolidate certain LTL shipments through a different mode of transportation, such as truckload, intermodal or rail; |

| |

• | the trend towards consolidation in the ground transportation industry may create other large carriers with greater financial resources and other competitive advantages relating to their size; |

| |

• | advances in technology require increased investments to remain competitive, and our customers may not be willing to accept higher prices to cover the cost of these investments; and |

| |

• | competition from non-asset-based logistics and freight brokerage companies may adversely affect our customer relationships and ability to maintain sufficient pricing. |

If we are unable to effectively compete with other LTL carriers, whether on the basis of price, service or otherwise, we may be unable to retain existing customers or attract new customers, either of which could have a material adverse effect on our business, financial condition and results of operations.

If our employees were to unionize, our operating costs would increase and our ability to compete would be impaired.

None of our employees are currently represented under a collective bargaining agreement. However, from time to time there have been efforts to organize our employees at various service centers. Further, Congress or one or more states could approve legislation and/or the National Labor Relations Board could render decisions or implement rule changes that could significantly affect our business and our relationship with our employees, including actions that could substantially liberalize the procedures for union organization. In addition, we can offer no assurance that the Department of Labor will not adopt new regulations or interpret existing regulations in a manner that would favor the agenda of unions, or that our employees will not unionize in the future, particularly if regulatory changes occur that facilitate unionization.

The unionization of our employees could have a material adverse effect on our business, financial condition and results of operations because:

| |

• | some shippers have indicated that they intend to limit their use of unionized trucking companies because of the threat of strikes and other work stoppages; |

| |

• | restrictive work rules could hamper our efforts to improve and sustain operating efficiency; |

| |

• | restrictive work rules could impair our service reputation and limit our ability to provide next-day services; |

| |

• | a strike or work stoppage could negatively impact our profitability and could damage customer and employee relationships; and |

| |

• | an election and bargaining process could divert management’s time and attention from our overall objectives and impose significant expenses. |

If we are unable to successfully execute our growth strategy, our business and future results of operations may suffer.

Our growth strategy includes increasing the volume of freight moving through our existing service center network, selectively expanding our geographic footprint and broadening the scope of our service offerings. In connection with our growth strategy, at various times, we have made selective acquisitions, purchased additional equipment, expanded and upgraded service centers and increased our sales and marketing efforts, and we expect to continue to do so. Our growth strategy exposes us to a number of risks, including the following:

| |

• | geographic expansion requires start-up costs that could expose us to temporary losses; |

| |

• | shortages of suitable real estate may limit our growth and geographic expansion and might cause congestion in our service center network, which could result in increased operating expenses; |

| |

• | growth may strain our management, capital resources, information systems and customer service; |

| |

• | hiring new employees may increase training costs and may result in temporary inefficiencies until those employees become proficient in their jobs; and |

| |

• | expanding our service offerings may require us to enter into new markets and encounter new competitive challenges. |

We cannot assure that we will overcome the risks associated with our growth strategy. If we fail to overcome those risks, we may not realize additional revenue or profits from our efforts, we may incur additional expenses and, therefore, our financial position and results of operations could be materially and adversely affected.

We may be unable to successfully consummate and integrate acquisitions as part of our growth strategy.

Growth through acquisitions has been a key component of our LTL growth strategy throughout our history. In the future, we may seek to acquire other LTL carriers as well as other complementary businesses. Exploration of potential acquisitions requires significant attention from our senior management team. In addition, we expect to compete for acquisition opportunities with other companies, some of which may have greater financial and other resources than we do. We cannot assure that we will

have sufficient cash with which to consummate an acquisition or otherwise be able to obtain financing for any acquisition. If we are unable to access sufficient funding for potential acquisitions, we may not be able to complete transactions that we otherwise find advantageous.

Any subsequent acquisition will entail numerous risks, including:

| |

• | we may not achieve anticipated levels of revenue, efficiency, cash flows and profitability; |

| |

• | we may experience difficulties managing businesses that are outside our historical core competency and markets; |

| |

• | we may underestimate the resources required to support acquisitions, which could disrupt our ongoing business and distract our management; |

| |

• | we may incur unanticipated costs to our infrastructure to support new business lines or separate legal entities; |

| |

• | we may be required to temporarily match existing customer pricing in the acquiree’s markets, which may be lower than the rates that we would typically charge for our services; |

| |

• | liabilities we assume could be greater than our original estimates or may not be disclosed to us at the time of acquisition; |

| |

• | we may incur additional indebtedness or we may issue additional equity to finance future acquisitions, which could be dilutive to our shareholders; |

| |

• | potential loss of key employees and customers of the acquired company; and |

| |

• | an inability to recognize projected cost savings and economies of scale. |

In addition, we may have difficulty integrating any acquired business and its operations, services and personnel into our existing operations, and such integration may require a significant amount of time and effort by our management team. To the extent we do not successfully avoid or overcome the risks or problems resulting from any acquisitions we undertake, there could be a material adverse effect on our business, financial condition and results of operations.

Our customers’ and suppliers’ businesses may be impacted by a downturn in the economy and/or a disruption of financial markets, which may decrease demand for our services.

Adverse economic conditions can negatively affect our customers’ business levels, the amount of transportation services they need, their ability to pay for our services and overall freight levels, all of which might impair our asset utilization. Customers encountering adverse economic conditions may be unable to obtain additional financing, or financing under acceptable terms, due to disruptions in the capital and credit markets. These customers represent a greater potential for bad debt losses, which may require us to increase our reserve for bad debt. Economic conditions resulting in bankruptcies of one or more of our large customers could have a significant impact on our financial position, results of operations or liquidity in a particular year or quarter. Further, when adverse economic times arise customers may bid out freight or select competitors that offer lower rates in an attempt to lower their costs and we might be forced to lower our rates or lose freight.

Our suppliers’ business levels also may be negatively affected by adverse economic conditions or financial constraints, which could lead to disruptions in the supply and availability of equipment, parts and services critical to our operations. A significant interruption in our normal supply chain could disrupt our operations, increase our costs and negatively impact our ability to serve our customers.

We also are subject to cost increases outside of our control that could materially reduce our profitability if we are unable to increase our rates sufficiently. Such cost increases include, but are not limited to, increases in fuel prices, driver wages, interest rates, taxes, tolls, license and registration fees, insurance, revenue equipment and healthcare for our employees.

Difficulties attracting and retaining qualified drivers could result in increases in driver compensation and could adversely affect our profitability and our ability to maintain or grow our fleet.

From time to time we have experienced difficulty in attracting and retaining sufficient numbers of qualified drivers and such shortages may recur in the future. Due in part to the time commitment, the physical strains of the work and the current industry conditions, the available pool of employee drivers has been declining. Regulatory requirements, including the Compliance, Safety, Accountability initiative (the "CSA") of the FMCSA, have also reduced the number of eligible drivers and may continue to do so in the future. Because of the intense competition for drivers, we may face difficulty maintaining or increasing our number of drivers. The compensation we offer our drivers is subject to market conditions that may require increases in driver compensation, which becomes more likely as economic conditions improve. If we are unable to attract and retain a sufficient number of drivers, we could be required to adjust our compensation packages, or operate with fewer trucks and face difficulty meeting customer demands, any of which could adversely affect our growth and profitability.

Insurance and claims expenses could significantly reduce our profitability.

We are exposed to claims related to cargo loss and damage, property damage, personal injury, workers’ compensation, group health and group dental. We have insurance coverage with third-party insurance carriers, but we assume a significant portion of the risk associated with these claims due to our SIRs and deductibles. Our operating results would be adversely affected if any of the following were to occur: (i) the number or severity of claims increases; (ii) we are required to accrue or pay additional amounts because the claims prove to be more severe than our original assessment; or (iii) claims exceed our excess coverage amounts. If claims exceed our SIR or deductible levels or insurance market conditions change, insurers could raise premiums for excess coverage to cover their expenses and anticipated future losses. In addition, insurance companies require us to obtain letters of credit to collateralize our SIR or deductible levels. If these requirements increase, our borrowing capacity could be adversely affected.

Healthcare legislation may increase our costs and reduce our future profitability.

To attract and retain employees, we maintain a competitive health insurance plan for our employees and their dependents. We cannot predict the impact that any state or federal healthcare legislation or regulation, including the Patient Protection and Affordable Care Act, will have on our operations, but we expect costs associated with providing benefits under employee medical plans to continue to increase. Rising healthcare costs in the United States could result in significant long-term costs to us, which could have a material adverse effect on our operating results. In addition, rising healthcare costs could force us to make further changes to our benefits program, which could negatively impact our ability to attract and retain employees.

We have significant ongoing cash requirements that could limit our growth and affect our profitability if we are unable to obtain sufficient capital.

Our business is highly capital intensive. We generally finance our capital expenditures and planned growth with existing cash, cash flow from operations, issuance of debt and through available borrowings under our existing senior unsecured credit agreement. We may require additional capital to finance long-term real estate purchase opportunities and acquisitions, which we may fund through additional debt or through equity offerings. If we are unable in the future to generate sufficient cash from our operations or raise capital by accessing the debt and equity markets, we may be forced to limit our growth and operate our equipment for longer periods of time, which could have a material adverse effect on our operating results.

Our business also has significant ongoing operating cash requirements. If our cash requirements are high or our cash flow from operations is low during particular periods, we may need to seek additional financing, which could be costly or difficult to obtain.

Limited supply and increased prices for new equipment may adversely affect our earnings and cash flow.

We may face difficulty in purchasing new equipment due to decreased supply and increased costs. Investment in new equipment is a significant part of our annual capital expenditures and we require an available supply of tractors and trailers from equipment manufacturers to operate and grow our business. We are also subject to shortages in raw materials that are required for the production of critical operating equipment and supplies, such as shortages in rubber or steel.

The price of our equipment may also be adversely affected in the future by regulations on newly manufactured tractors and diesel engines. We have incurred significant increases in the cost of tractors due to regulations issued by the U.S. Environmental Protection Agency (the “EPA”) and various state agencies that require progressive reductions in exhaust emissions from diesel engines. Beginning in October 2002, new diesel engines were required to meet these new emission limits. Some of the regulations required reductions in the sulfur content of diesel fuel beginning in June 2006 and the introduction of emissions after-treatment devices on newly-manufactured engines and vehicles beginning with model-year 2007. The final phase of these regulations required reduced nitrogen and non-methane hydrocarbon emissions beginning with model-year 2010. Beginning in 2013, these regulations also required that all heavy-duty diesel engines built for highway applications over 14,000 pounds include certified onboard diagnostics systems to monitor emissions. These regulations have resulted in higher prices for tractors and diesel engines and increased operating and maintenance costs, and there can be no assurance that continued increases in pricing or costs will not have an adverse effect on our business and results of operations.

We may be adversely impacted by fluctuations in the availability and price of diesel fuel.

Diesel fuel is a critical component of our operations and a significant operating expense for our business. Diesel fuel prices and fuel availability can be impacted by factors beyond our control, such as natural or man-made disasters, adverse weather conditions, political events, disruption or failure of technology or information systems, price and supply decisions by oil producing countries and cartels, terrorist activities, armed conflict and world supply and demand imbalances. We maintain fuel storage and pumping facilities at many of our service center locations; however, we may be susceptible to fuel shortages at certain locations that could cause us to incur additional expense to ensure adequate supply on a timely basis to prevent a disruption to our service schedules. An interruption in the supply of diesel fuel could have a material adverse effect on our operating results.

We do not hedge against the risk of diesel fuel price increases. An increase in diesel fuel prices or diesel fuel taxes, or any change in federal or state regulations that results in such an increase, could have a material adverse effect on our operating results. We have fuel surcharge programs in place with a majority of our customers, which help offset the negative impact of the increased cost of diesel fuel and other petroleum-based products. However, we also incur fuel costs that cannot be recovered even with respect to customers with which we maintain fuel surcharge programs, such as those costs associated with empty miles or the time when our engines are idling. Because our fuel surcharge recovery lags behind changes in fuel prices, our fuel surcharge recovery may not capture the increased costs we pay for fuel, especially when prices are rising, leading to fluctuations in our levels of reimbursement. We regularly monitor the components of our pricing, including fuel surcharges, and address individual account profitability issues with our customers when necessary; however, there can be no assurance that fuel surcharges can be maintained indefinitely or will be sufficiently effective in offsetting increases in diesel fuel prices.

We are subject to various environmental laws and regulations, and costs of compliance with, liabilities under, or violations of, existing or future environmental laws or regulations could adversely affect our business.

We are subject to various federal, state and local environmental laws and regulations that govern, among other things, the emission and discharge of hazardous materials into the environment, the presence of hazardous materials at our properties or in our vehicles, fuel storage tanks, the transportation of certain materials and the discharge or retention of storm water. Under certain environmental laws, we could also be held responsible for any costs relating to contamination at our past or present facilities and at third-party waste disposal sites, as well as costs associated with the clean-up of accidents involving our vehicles. Environmental laws have become and are expected to continue to be increasingly more stringent over time, and there can be no assurance that our costs of complying with current or future environmental laws or liabilities arising under such laws will not have a material adverse effect on our business, operations or financial condition.

In addition to the EPA regulations on exhaust emissions with which we must comply, there is an increased regulatory focus on climate change and greenhouse gas emissions in the United States. We are also subject to increasing sensitivity to sustainability issues. This increased focus on sustainability may result in new regulations and/or customer requirements that could adversely impact our business. Any future limitations on the emission of greenhouse gases, other environmental legislation or customer sustainability requirements could increase our future capital expenditures and have an adverse impact on our financial condition, results of operations and liquidity.

We are subject to the risks of litigation and governmental proceedings, which could adversely affect our business.

We are, and in the future may be, subject to legal and governmental proceedings and claims. The parties in such legal actions may seek amounts from us that may not be covered in whole or in part by insurance. Defending ourselves against such legal actions could result in significant costs and could require a substantial amount of time and effort by our management team. We cannot predict the outcome of litigation or governmental proceedings to which we are a party or whether we will be subject to future legal actions. As a result, the potential costs associated with legal actions against us could adversely affect our business, financial condition or results of operations.

We are subject to various risks arising from our international business operations and relationships, which could adversely affect our business.

We arrange for transportation and logistics services to and from various international locations and are subject to both the risks of conducting international business and the requirements of the Foreign Corrupt Practices Act of 1977 (the "FCPA"). Failure to comply with the FCPA may result in legal claims against us. In addition, we face other risks associated with international operations and relationships, which may include restrictive trade policies, imposition of duties, taxes or government royalties imposed by foreign governments.

We operate in a highly regulated industry, and increased costs of compliance with, or liability for violation of, existing or future regulations could have a material adverse effect on our business.

We are regulated by the DOT and by various state agencies. These regulatory authorities have broad powers, generally governing matters such as authority to engage in motor carrier operations, as well as motor carrier registration, driver hours of service, safety and fitness of transportation equipment and drivers, transportation of hazardous materials, certain mergers and acquisitions and periodic financial reporting. In addition, the trucking industry is subject to regulatory and legislative changes from a variety of other governmental authorities, which address matters such as: (i) increasingly stringent environmental, occupational safety and health regulations; (ii) limits on vehicle weight and size; (iii) ergonomics; (iv) port security; and (v) hours of service. In addition, we are subject to compliance with cargo-security and transportation regulations issued by the TSA within the U.S. Department of Homeland Security. Regulatory requirements, and changes in regulatory requirements, may affect our business or the economics of the industry by requiring changes in operating practices or by influencing the demand for and increasing the costs of providing transportation services.

In October 2009, the U.S. Court of Appeals for the District of Columbia Circuit ordered the FMCSA to review and re-issue rules governing hours of service for commercial truck drivers by July 26, 2011. This deadline was extended and on December 22, 2011, the FMCSA issued its final rule, which mandated compliance by July 1, 2013. The 2011 rule reduced the maximum number of hours a truck driver could work each week to 70 hours from the former 82-hour limit. The 2011 rule maintained the maximum 11-hour daily driving limit, but required drivers to take a 30-minute break prior to working beyond

eight hours. The 2011 rule also modified the “34-hour restart” provision to include two periods of rest between 1 a.m. and 5 a.m., and limited a restart to once every 168 hours. On December 16, 2014, however, the 2015 Omnibus Appropriations Bill temporarily suspended enforcement of certain aspects of the restart provisions until September 30, 2015. Specifically, the new law temporarily eliminated the requirements for two rest periods between 1 a.m. and 5 a.m. and the 168-hour minimum restart provision. During this suspension period, the law directs the Secretary of the DOT to conduct a study of the operational, safety, health and fatigue aspects of the restart provisions in effect before and after July 1, 2013.

Implementation of the 2011 rule on July 1, 2013 required us to make certain changes in our operating procedures. These changes increased our operating costs by limiting the productivity of our drivers. While the suspension of certain aspects of the restart provisions should allow us to regain some of this lost productivity, the suspension is temporary and we do not plan to make significant changes to our operations. As a result, we could continue to incur higher operating costs than we had before the 2011 rule went into effect.

We are subject to future rulemaking by the FMCSA and other regulatory agencies, which could be more stringent, require additional changes to our operations, increase our operating costs or otherwise adversely impact our results of operations.

The FMCSA’s CSA initiative could adversely impact our ability to hire qualified drivers, meet our growth projections and maintain our customer relationships, each of which could adversely impact our results of operations.

The CSA includes compliance and enforcement initiatives designed to monitor and improve commercial motor vehicle safety by measuring the safety record of both the motor carrier and the driver. These measurements are scored and used by the FMCSA to identify potential safety risks and to direct enforcement action. Certain measurements and scores collected by the CSA from transportation companies are available to the general public on the FMCSA’s website.

Our CSA scores are dependent upon our safety and compliance experience, which could change at any time. In addition, the safety standards prescribed in CSA could change and our ability to maintain an acceptable score could be adversely impacted. If we receive an unacceptable CSA score, our relationships with our customers could be damaged, which could result in a loss of business.

The requirements of CSA could shrink the industry’s pool of drivers as those with unfavorable scores could leave the industry. As a result, the costs to attract, train and retain qualified drivers could increase. In addition, a shortage of qualified drivers could increase driver turnover, decrease asset utilization, limit growth and adversely impact our results of operations.

Our results of operations may be affected by seasonal factors and harsh weather conditions.

Our operations are subject to seasonal trends common in the trucking industry. Our operating margins in the first quarter are normally lower due to reduced demand during the winter months. Harsh weather can also adversely affect our performance by reducing demand and reducing our ability to transport freight, which could result in decreased revenue and increased operating expenses.

If we are unable to retain our key employees, our financial condition, results of operations and liquidity could be adversely affected.

Our success will continue to depend upon the experience and leadership of our key employees and executive officers. In that regard, the loss of the services of any of our key personnel could have a material adverse effect on our financial condition, results of operations and liquidity if we are unable to secure replacement personnel that have sufficient experience in our industry and in the management of our business. If we are unable to continue to develop and retain a core group of management personnel and execute succession planning strategies, our business could be negatively impacted in the future.

Our principal shareholders control a large portion of our outstanding common stock.

Earl E. Congdon, David S. Congdon, John R. Congdon, Jr. and members of their respective families beneficially own an aggregate of approximately 25% of the outstanding shares of our common stock. As long as the Congdon family controls a large portion of our voting stock, they may be able to significantly influence the election of the entire Board of Directors and the outcome of all matters involving a shareholder vote. The Congdon family’s interests may differ from the interests of other shareholders and the status of their ownership could change at their discretion.

Our financial results may be adversely impacted by potential future changes in accounting practices.

Future changes in accounting standards or practices, and related legal and regulatory interpretations of those changes, may adversely impact public companies in general, the transportation industry or our operations specifically. New accounting standards or requirements, such as a conversion from U.S. generally accepted accounting principles to International Financial Reporting Standards, could change the way we record revenues, expenses, assets and/or liabilities or could be costly to implement. These types of regulations could have a negative impact on our financial position, liquidity, results of operations and/or access to capital.

Our information technology systems are subject to cyber and other risks, some of which are beyond our control, which could have a material adverse effect on our business, results of operations and financial position.

We are reliant on the proper functioning and availability of our information systems for our operations as well as providing a value-added service to our customers. Our information systems, including our accounting systems and communications and data processing systems, are integral to the efficient operation of our business. It is critical that the data processed by these systems remain confidential, as it often includes competitive customer information, confidential customer transaction data, employee records and key financial and operational results and statistics. Cyber incidents that impact the security, availability, reliability, speed, accuracy or other proper functioning of these systems and measures, including outages, computer viruses, break-ins and similar disruptions, could have a significant impact on our operations. Although our information systems are protected through physical and software safeguards as well as redundant systems, network security measures and backup systems considered appropriate by management, it is not practicable to protect against the possibility of power loss, telecommunications failures, cybersecurity attacks, and other cyber incidents in every potential circumstance that may arise. A significant cyber incident, including system failure, security breach, disruption by malware, or other damage, could interrupt or delay our operations, damage our reputation, cause a loss of customers, expose us to a risk of loss or litigation, and/or cause us to incur significant time and expense to remedy such an event, any of which could have a material adverse impact on our results of operations and financial position.

We rely heavily on information technology systems and any disruption to our technology infrastructure or failures of essential services upon which our information technology platforms rely could cause us to incur costs or result in a loss of business, which may have a material adverse effect on our results of operations and financial condition.

Our information technology systems are complex and require ongoing investments and enhancements to meet our internal and our customers’ requirements. Our information technology systems also depend upon the Internet, third-party service providers, global communications providers, satellite-based communications systems, the electric utilities grid, electric utility providers and telecommunications providers. We have no control over the operation, quality, or maintenance of these services or whether vendors will improve their services or continue to provide services that are essential to our business. Disruptions due to transitional challenges in upgrading or enhancing our technology systems or failures in the services upon which our information technology platforms rely, which may arise from adverse weather conditions or natural calamities, such as floods, hurricanes, earthquakes or tornadoes; illegal acts, including terrorist attacks; human error or systems modernization initiatives; and/or other disruptions, may adversely affect the services we provide, which could increase our costs or result in a loss of customers that could have a material adverse effect on our results of operations and financial position.

Misuse of social media outlets could damage our reputation and adversely affect our financial condition.

Customers, competitors, employees and other individuals continue to increase the use of social media outlets, and we maintain and manage our own corporate presence through various social media outlets. We support new ways of sharing data and communicating through these social media outlets. However, information distributed via social networking could result in unfavorable publicity about us being disseminated quickly and broadly. This unfavorable publicity could damage our reputation and may result in a reduction in demand for our services or the loss of customers that could have a negative impact on our financial condition, results of operations and liquidity.

A decrease in the demand and value of used equipment may impact our results of operations.

As we purchase new tractors as part of our normal replacement cycle each year, we rely on the used equipment market to dispose of our older equipment. Oversupply in the transportation industry as well as adverse domestic and foreign economic conditions can negatively impact the demand for used tractors and, therefore, reduce the value we can obtain on our used equipment. If we are unable to sell our older equipment at or above our salvage value, the resulting losses could have a significant impact on our results of operations.

If we raise additional capital in the future, your ownership in us could be diluted.

Any issuance of equity we may undertake in the future to raise additional capital could cause the price of our common stock to decline, or require us to issue shares at a price that is lower than that paid by holders of our common stock in the past, which would result in those newly issued shares being dilutive. If we obtain funds through a credit facility or through the issuance of debt or preferred securities, these obligations and securities would likely have rights senior to your rights as a common shareholder, which could impair the value of our common stock.

The market value of our common stock may fluctuate and could be substantially affected by various factors.

The price of our common stock on the NASDAQ Global Select Market constantly changes. We expect that the market price of our common stock will continue to fluctuate as a result of a variety of factors, many of which are beyond our control. These factors include, among others:

| |

• | actual or anticipated variations in earnings, financial or operating performance or liquidity; |

| |

• | changes in analysts’ recommendations or projections; |

| |

• | failure to meet analysts’ projections; |

| |

• | general economic and capital market conditions; |

| |

• | announcements of developments related to our business; |

| |

• | operating and stock performance of other companies deemed to be peers; |

| |

• | actions by government regulators; and |

| |

• | news reports of trends, concerns and other issues related to us or our industry, including changes in regulations. |

Our common stock price may fluctuate significantly in the future, and these fluctuations may be unrelated to our performance. General market price declines or market volatility in the future could adversely affect the price of our common stock, and the current market price of our common stock may not be indicative of future market prices.

Our articles of incorporation, our bylaws and Virginia law contain provisions that could discourage, delay or prevent a change in our control or our management.

Provisions of our articles of incorporation, bylaws and the laws of Virginia, the state in which we are incorporated, may discourage, delay or prevent a change in control of us or a change in management that shareholders may consider favorable. These provisions:

| |

• | limit who may call a special meeting of shareholders; |

| |

• | require shareholder action by written consent to be unanimous; |

| |

• | establish advance notice requirements for nominations for election to our Board of Directors or for proposing matters that can be acted upon at shareholder meetings; |

| |

• | may make it difficult to merge with or otherwise absorb a Virginia corporation acquired in a tender offer for the three years after the acquisition; and |

| |

• | may make an unsolicited attempt to gain control of us more difficult by restricting the right of specified shareholders to vote newly acquired large blocks of stock. |

These provisions could discourage proxy contests and make it more difficult for you and other shareholders to take certain corporate actions. These provisions could also limit the price that investors might be willing to pay in the future for shares of our common stock.

ITEM 1B. UNRESOLVED STAFF COMMENTS

None.

ITEM 2. PROPERTIES

We own our principal executive office located in Thomasville, North Carolina, consisting of a two-story office building of approximately 165,000 square feet on 31.8 acres of land. At December 31, 2014, we operated 222 service centers, of which 176 were owned and 46 were leased. Our service centers that are owned include most of our larger facilities and account for approximately 90% of the total door capacity in our network. With the exception of our Chicago, Illinois facility, we own our major breakbulk facilities. Each of our major breakbulk facilities is listed below with the number of doors as of December 31, 2014.

|

| | |

Service Center | | Doors |

Morristown, Tennessee | | 347 |

Indianapolis, Indiana | | 318 |

Harrisburg, Pennsylvania | | 300 |

Memphis, Tennessee | | 267 |

Rialto, California | | 265 |

Dallas, Texas | | 234 |

Atlanta, Georgia | | 227 |

Greensboro, North Carolina | | 219 |

Salt Lake City, Utah | | 150 |

Chicago, Illinois | | 134 |

Our 222 facilities are strategically dispersed over the states in which we operate. At December 31, 2014, the terms of our leased properties ranged from month-to-month to a lease that expires in 2039. We believe that as current leases expire, we will be able to renew them or find comparable facilities without incurring any material negative impact on service to our customers or our operating results.

We also own 12 non-operating service center properties. Eight of these properties are leased to third parties with lease terms that range from month-to-month to a lease that expires in 2019.

We believe that all of our properties are in good repair and are capable of providing the level of service required by current business levels and customer demands. In addition, we believe we have sufficient capacity in our service center network to accommodate increased demand for our services.

ITEM 3. LEGAL PROCEEDINGS

We are involved in various legal proceedings and claims that have arisen in the ordinary course of our business and have not been fully adjudicated, some of which are covered in whole or in part by insurance. Certain of these claims include class-action allegations. Our management does not believe that these actions, when finally concluded and determined, will have a material adverse effect upon our financial position, liquidity or results of operations.

ITEM 4. MINE SAFETY DISCLOSURES

Not applicable.

PART II

ITEM 5. MARKET FOR REGISTRANT’S COMMON EQUITY, RELATED STOCKHOLDER MATTERS AND ISSUER PURCHASES OF EQUITY SECURITIES

Common Stock and Dividend Information

Our common stock is traded on the NASDAQ Global Select Market ("Nasdaq") under the symbol ODFL. At February 23, 2015, there were 50,983 holders of our common stock, including 116 shareholders of record. We did not pay any dividends on our common stock during fiscal year 2014 or 2013, and we have no current plans to declare or pay any dividends on our common stock during fiscal year 2015. For information concerning restrictions on our ability to make dividend payments, see Liquidity and Capital Resources in Item 7, “Management’s Discussion and Analysis of Financial Condition and Results of Operations” and Note 2 in Item 8, “Financial Statements and Supplementary Data” of this report.

The following table sets forth the high and low sales price of our common stock for the periods indicated, as reported by Nasdaq:

|

| | | | | | | | | | | | | | | | |

| | 2014 |

| | First Quarter | | Second Quarter | | Third Quarter | | Fourth Quarter |

| |

High | | $ | 57.48 |

| | $ | 65.35 |

| | $ | 72.63 |

| | $ | 81.48 |

|

Low | | $ | 49.76 |

| | $ | 53.63 |

| | $ | 61.17 |

| | $ | 62.17 |

|

|

| | | | | | | | | | | | | | | | |

| | 2013 |

| | First Quarter | | Second Quarter | | Third Quarter | | Fourth Quarter |

| |

High | | $ | 38.76 |

| | $ | 44.00 |

| | $ | 47.66 |

| | $ | 53.34 |

|

Low | | $ | 34.58 |

| | $ | 35.17 |

| | $ | 41.93 |

| | $ | 45.15 |

|

The following table provides information regarding our repurchases of our common stock during the fourth quarter of 2014.

|

| | | | | | | | | | | | | | |

ISSUER PURCHASES OF EQUITY SECURITIES |

| | | | | | | | |

| | Total Number of Shares Purchased | | Average Price Paid per Share | | Total Number of Shares Purchased as Part of Publicly Announced Programs | | Approximate Dollar Value of Shares that May Yet Be Purchased Under the Programs |

| |

October 1-31, 2014 | | — |

| | $ | — |

| | — |

| | $ | — |

|

November 1-30, 2014 | | — |

| | $ | — |

| | — |

| | $ | — |

|

December 1-31, 2014 | | 70,620 |

| | $ | 78.34 |

| | 70,620 |

| | $ | 194,467,625 |

|

Total | | 70,620 |

| | $ | 78.34 |

| | 70,620 |

| | |

On November 10, 2014, we announced that our Board of Directors approved a stock repurchase program authorizing us to repurchase up to an aggregate of $200.0 million of our outstanding common stock. We may repurchase shares from time-to-time in open market purchases or through privately negotiated transactions. The program expires on November 6, 2016. Shares of our common stock repurchased by us under the repurchase program are canceled at the time of repurchase and are authorized but unissued shares of our common stock.

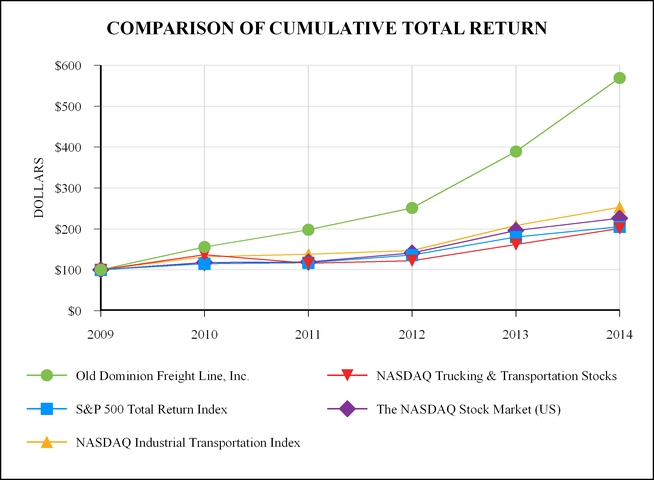

Performance Graph

The following graph compares the total shareholder cumulative returns, assuming the reinvestment of all dividends, of $100 invested on December 31, 2009, in (i) our common stock, (ii) the NASDAQ Industrial Transportation Index, (iii) the S&P 500 Total Return Index, (iv) the NASDAQ Trucking & Transportation Stocks and (v) The NASDAQ Stock Market (US) for the five-year period ended December 31, 2014.

As a result of a change in the total return data made available to us through our vendor provider, our performance graphs going forward will use a comparable index provided by NASDAQ OMX Global Indexes. We have included the NASDAQ Trucking & Transportation Stocks and The NASDAQ Stock Market (US) for comparative purposes, however, these indices will be replaced with the NASDAQ Industrial Transportation Index and the S&P 500 Total Return Index going forward.

Cumulative Total Return

|

| | | | | | | | | | | | | | | | | | | | | | | | |

| | 12/31/09 | | 12/31/10 | | 12/31/11 | | 12/31/12 | | 12/31/13 | | 12/31/14 |

Old Dominion Freight Line, Inc. | | $ | 100 |

| | $ | 156 |

| | $ | 198 |

| | $ | 251 |

| | $ | 389 |

| | $ | 569 |

|

New Indices: | | | | | | | | | | | | |

S&P 500 Total Return Index | | $ | 100 |

| | $ | 115 |

| | $ | 117 |

| | $ | 136 |

| | $ | 180 |

| | $ | 205 |

|

NASDAQ Industrial Transportation Index | | $ | 100 |

| | $ | 132 |

| | $ | 138 |

| | $ | 147 |

| | $ | 208 |

| | $ | 253 |

|

Former Indices: | | | | | | | | | | | | |

NASDAQ Trucking & Transportation Stocks | | $ | 100 |

| | $ | 137 |

| | $ | 116 |

| | $ | 122 |

| | $ | 162 |

| | $ | 201 |

|

The NASDAQ Stock Market (US) | | $ | 100 |

| | $ | 118 |

| | $ | 119 |

| | $ | 141 |

| | $ | 196 |

| | $ | 226 |

|

ITEM 6. SELECTED FINANCIAL DATA

|

| | | | | | | | | | | | | | | | | | | | |

| | Year Ended December 31, |

(In thousands, except per share amounts) | | | | | | | | | | |

| | 2014 | | 2013 | | 2012 | | 2011 | | 2010 |

Operating Data: | | | | | | | | | | |

Revenue from operations | | $ | 2,787,897 |

| | $ | 2,337,648 |

| | $ | 2,134,579 |

| | $ | 1,903,800 |

| | $ | 1,501,848 |

|

Depreciation and amortization expense | | 146,466 |

| | 127,072 |

| | 110,743 |

| | 90,820 |

| | 80,362 |

|

Total operating expenses | | 2,346,590 |

| | 1,999,210 |

| | 1,849,325 |

| | 1,669,728 |

| | 1,364,109 |

|

Operating income | | 441,307 |

| | 338,438 |

| | 285,254 |

| | 234,072 |

| | 137,739 |

|

Interest expense, net (1) | | 6,502 |

| | 9,473 |

| | 11,428 |

| | 13,887 |

| | 12,465 |

|

Provision for income taxes | | 165,000 |

| | 122,573 |

| | 103,646 |

| | 80,614 |

| | 48,775 |

|

Net income | | 267,514 |

| | 206,113 |

| | 169,452 |

| | 139,470 |

| | 75,651 |

|

| | | | | | | | | | |

Per Share Data: | | | | | | | | | | |

Diluted earnings per share | | $ | 3.10 |

| | $ | 2.39 |

| | $ | 1.97 |

| | $ | 1.63 |

| | $ | 0.90 |

|

| | | | | | | | | | |